| Irú ìpele irin | Irin ìkọ́lé: |

| Boṣewa |

|

| Àwọn ìlànà ìṣelọ́pọ́ | Àwo irin, Àwo, Okùn, Pẹpẹ alapin, Pẹpẹ yíká, Irin onírin, wáyà, Gbogbo onírúurú àwọn ohun èlò ìfọṣọ. |

| Ṣíṣe ẹ̀rọ | Yíyípo Lilọ kiri Lilọ Lilọ ihò jinjin: gigun ti o pọju awọn mita 9.8. |

| Ipin iṣẹ | Irin onigun mẹrin: 1mm si 2000mm Irin onigun mẹrin: 10mm si 1000mm Awo/dì irin: 0.08mm si 800mm Fífẹ̀: 10mm sí 1500mm Àkókò Ìwọ̀n: A lè pèsè èyíkéyìí ìwọ̀n ìwọ̀n gẹ́gẹ́ bí ohun tí oníbàárà bá fẹ́. Fífi ṣe àgbékalẹ̀: Àwọn ọ̀pá pẹ̀lú ẹ̀gbẹ́/páìpù/páìpù/slugs/donuts/cubes/àwọn ìrísí mìíràn Àwọn ọpọ́n omi: OD: φ4-410 mm, pẹ̀lú ìfúnpọ̀ ògiri láti 1-35 mm. |

| Ìtọ́jú ooru | Ṣíṣe déédé, fífún omi, fífún omi, pípa omi, fífún omi àti fífún omi ní ìgbóná, fífún omi ní ìgbóná, fífún omi ní ìgbóná, fífún omi ní ìgbóná, fífún omi ní ìgbóná |

ÀWỌN OHUN ÈLÒ KẸ́MÍKÀ ÀTI ÌṢẸ̀KẸ̀MÍ AWS E10015-D2:

| C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni |

| 0.15 | 0.6 | 1.65-2.0 | 0.03 | 0.03 | ≤0.9 | |

| Mo | Al | Cu | Nb | Ti | V | Ce |

| 0.25-0.45 | ||||||

| N | Co | Pb | B | Òmíràn |

Àwọn OHUN ÈLÒ ÌṢẸ́-Ẹ̀RỌ:

| Àwọn dúkìá | Àwọn ipò | ||

| T (°C) | Ìtọ́jú | ||

| Ìwọ̀n (×1000 kg/m3) | 7.7-8.03 | 25 |

|

| Ìpíndọ́gba Poisson | 0.27-0.30 | 25 |

|

| Modulu Elastic (GPa) | 190-210 | 25 |

|

| Agbára ìfàyà (Mpa) | 1158 | 25 | epo ti a pa, ti a fi igi gún, ti a fi gbóná ni iwọn otutu 425°C |

| Agbára Ìmújáde (Mpa) | 1034 | ||

| Gbigbe (%) | 15 | ||

| Idinku ni Agbegbe (%) | 53 | ||

| Líle (HB) | 335 | 25 | epo ti a pa, ti a fi igi gún, ti a fi gbóná ni iwọn otutu 425°C |

| Àwọn dúkìá | Àwọn ipò | ||

| T (°C) | Ìtọ́jú | ||

| Ìgbékalẹ̀ Ooru (W/mK) | 42.7 | 100 | |

| Ooru Kan pato (J/kg-K) | 477 | 50-100 | |

ÀWỌN OHUN ÈLÒ TÍ A NÍPA TI ARA:

| Iye | Iye | Ẹyọ kan |

| Ìfẹ̀sí ooru | 16 - 17 | e-6/K |

| Agbara itusilẹ ooru | 16 - 16 | W/mK |

| Ooru pàtó kan | 500 - 500 | J/kg.K |

| Iwọn otutu ti o yo | 1370 - 1400 | °C |

| Iwọn otutu iṣẹ | 0 - 500 | °C |

| Ìwọ̀n | 8000 - 8000 | kg/m3 |

| Àìfaradà | 0.7 - 0.7 | Ohm.mm2/m |

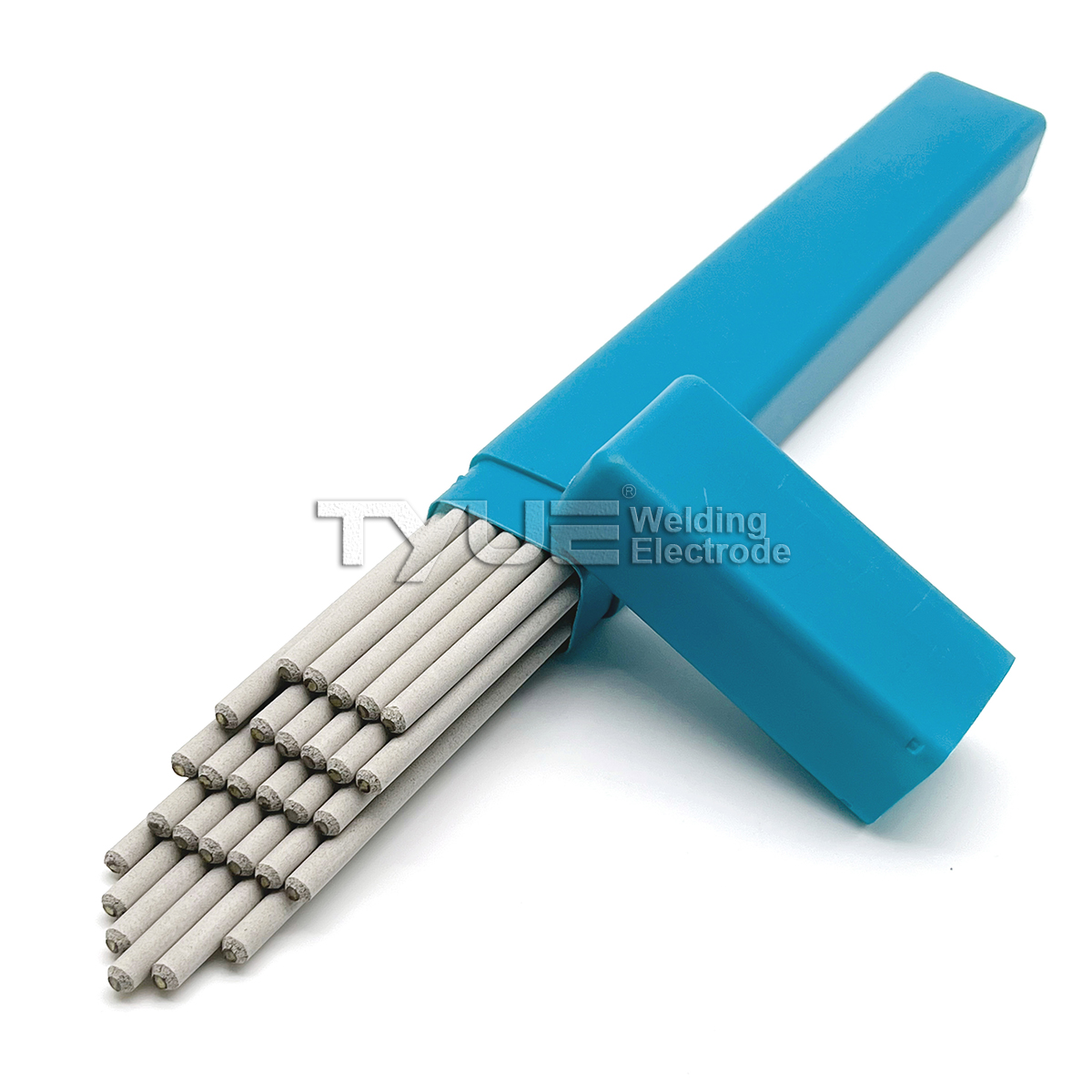

Àwọn Electrodes Alurinmorin Haidrojin Kekere E7015-G

ÀPÈJÚWE:

Ó jẹ́ ọ̀pá ìsopọ̀ irin tí ó ní ìwọ̀n otútù díẹ̀ pẹ̀lú ìbòrí hydrogen sodium tí ó ní nickel. A lè ṣe ìsopọ̀ ìsopọ̀ ìyípadà dc ní gbogbo ipò. Ní -80°C, irin ìsopọ̀ náà ṣì ní agbára ìkọlù tí ó dára.

LÍLO:

Irin ti a fi weld ṣe -80°C ti o ṣiṣẹ pẹlu eto irin 1.5Ni.

ÀWỌN KẸ́MÍKÍMÌ IRÍ TÍ A FI SÍLẸ̀:

| C | Mn | Si | Ni | S | P | |

| Boṣewa | ≤0.08 | ≤1.25 | ≤0.60 | ≥1.00 | ≤0.035 | ≤0.035 |

| Idanwo | 0.045 | 0.60 | 0.27 | 1.80 | 0.010 | 0.015 |

Iṣẹ́ Mẹ́kínẹ́ẹ̀kì Irin Tí A Fi Sílẹ̀:

| Agbára Ìfàsẹ́yìn Rm (MPa) | Ìmújáde Agbára Rel (MPa) | Gbigbe A (%) | -80°C Impact Value Akv (J) | |

| Boṣewa | ≥490 | ≥390 | ≥22 | ≥27 |

| Idanwo | 530 | 445 | 30 | 100 |

ÌṢẸ́ṢẸ̀ TÍ A Ń TỌ́KASÍ (DC+):

| Ìwọ̀n ìlà opin (mm) | 3.2 | 4.0 | 5.0 | |

| Gígùn (mm) | 350 | 400 | 400 | |

| Lọ́wọ́lọ́wọ́ (A) | 90-120 | 140-180 | 180-210 |

| E12015-G | Gẹ́gẹ́ bí GB E8515-G Bá AWS E12015-G mu |

Ìfihàn: E12015-G jẹ́ irú ẹ̀rọ irin alágbára gíga tí ó ní àwọ̀ kékeré pẹ̀lú ìbòrí oríṣi hydrogen tí ó ní àwọ̀ kékeré. DCRP (Taara Ọwọ́ Ìyípadà). Alurinmorin ipò gbogbo.

Awọn ohun elo: Ti a lo fun alurinmorin awọn ẹya irin alagbara-kekere ti alloy pẹlu agbara fifẹ ti nipa 830MPa.

Ìṣètò Kẹ́míkà ti Irin Tí A Fi Sílẹ̀ (%)

| Àkójọpọ̀ Kẹ́míkà | C | Mn | Si | S | P | Mo |

| Iye Ẹri Iṣeduro | ≤0.15 | ≥1.00 | 0.4~0.8 | ≤0.035 | ≤0.035 | 0.60~1.20 |

| Àbájáde Gbogbogbò | ≤0.10 | ~1.50 | ≤0.70 | ≤0.020 | ≤0.020 | ~0.90 |

Àwọn Ohun Èlò Ìdárayá ti Irin Tí A Fi Sílẹ̀

| Ohun Idanwo | Rm(MPa) | ReL tàbíRojú ìwé 0.2(Mpa) | A(%) | KV2(J) |

| Iye Ẹri Iṣeduro | ≥830 | ≥740 | ≥12 | - (iwọn otutu deede) |

| Àbájáde Gbogbogbò | 860~950 | ≥750 | 12~20 | ≥27 |

Àkóónú Hídrójìn Tí Ó Lè Túká Nínú Irin Tí A Fi Sílẹ̀: ≤5.0ml/100g (Kromatografi)

Àyẹ̀wò X-ray Radiographic: ⅠÌwọ̀n

ÀWỌN ÌTỌ́NI:

1. A gbọ́dọ̀ yan àwọn elekitirodu náà lábẹ́ 350-400℃ fún wákàtí kan kí a tó fi wọ́n sí orí ìsopọ̀, kí a sì fi wọ́n sí orí ìsopọ̀mọ́ra kí a sì fi wọ́n sí i nígbà tí a bá nílò wọn.

2. A gbọ́dọ̀ mú àwọn àbàwọ́n tí ó wà lórí ìsopọ̀ náà bí ipata kúrò, a sì gbọ́dọ̀ mú ìsopọ̀ náà gbóná sí i ní ìwọ̀n 200℃.

3. A le mu alurinmorin naa wa labẹ iwọn otutu 600-650℃ lẹhin alurinmorin ki a le mu wahala inu kuro.