| Irin ite iru | Epo irin: |

| Standard |

|

| Awọn pato iṣelọpọ | Awo irin, Sheet, Coil, Pẹpẹ alapin, Pẹpẹ Yika, Irin Rin, Waya, Gbogbo iru ayederu. |

| Mchining | Titan Milling Lilọ Liluho iho jin: ipari max 9,8 mita. |

| Ibiti o ti iṣẹ | Yika igi irin: 1mm to 2000mm Irin apẹrẹ onigun: 10mm si 1000mm irin Awo / dì: 0.08mm to 800mm Iwọn: 10mm si 1500mm Lenth: A le pese awin eyikeyi ti o da lori ibeere alabara. Forging: Awọn ọpa pẹlu awọn ẹgbẹ / awọn paipu / awọn tubes / slugs / donuts / cubes / awọn apẹrẹ miiran Awọn iwẹ: OD: φ4-410 mm, pẹlu sisanra odi ti o wa lati 1-35 mm. |

| Ooru itọju | Deede,Annealing,Tempering,Quenching,Hardening ati tempering,Seasoning,Ile dada,Carburizing |

AWS E10015-D2 IṢẸ́ KẸKẸMIKÚN ÀTI IṢẸ́ Ẹ̀rọ:

| C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni |

| 0.15 | 0.6 | 1.65-2.0 | 0.03 | 0.03 | ≤0.9 | |

| Mo | Al | Cu | Nb | Ti | V | Ce |

| 0.25-0.45 | ||||||

| N | Co | Pb | B | Omiiran |

Awọn ohun-ini ẹrọ:

| Awọn ohun-ini | Awọn ipo | ||

| T (°C) | Itọju | ||

| Ìwúwo (×1000 kg/m3) | 7.7-8.03 | 25 |

|

| Iye owo ti Poisson | 0.27-0.30 | 25 |

|

| Modulu Rirọ (GPa) | 190-210 | 25 |

|

| Agbara Fifẹ (Mpa) | 1158 | 25 | epo ti a pa, ọkà daradara, ti o gbona ni 425°C |

| Agbara ikore (Mpa) | 1034 | ||

| Ilọsiwaju (%) | 15 | ||

| Idinku ni Agbegbe (%) | 53 | ||

| Lile (HB) | 335 | 25 | epo ti a pa, ọkà daradara, ti o gbona ni 425°C |

| Awọn ohun-ini | Awọn ipo | ||

| T (°C) | Itọju | ||

| Imudara Ooru (W/mK) | 42.7 | 100 | |

| Ooru kan pato (J/kg-K) | 477 | 50-100 | |

Awọn ohun-ini ARA:

| Opoiye | Iye | Ẹyọ |

| Gbona imugboroosi | 16-17 | e-6/K |

| Gbona elekitiriki | 16-16 | W/mK |

| Ooru pato | 500 - 500 | J/kg.K |

| yo otutu | 1370-1400 | °C |

| Iwọn otutu iṣẹ | 0-500 | °C |

| iwuwo | 8000 - 8000 | kg/m3 |

| Resistivity | 0.7 - 0.7 | Ohm.mm2/m |

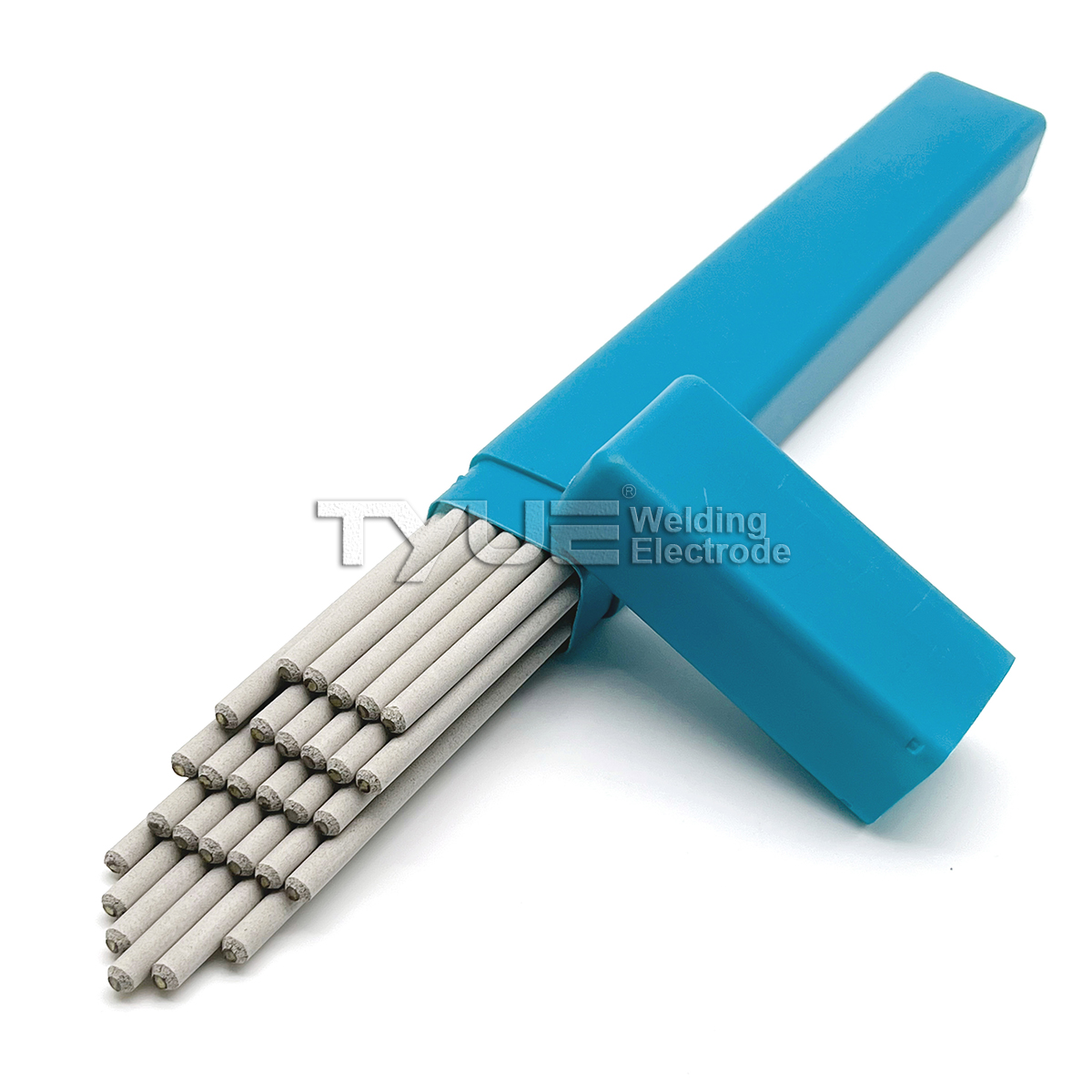

E7015-G Low Hydrogen Sodium Coating Welding Electrodes

Apejuwe:

O ti wa ni a kekere otutu irin alurinmorin ọpá pẹlu kekere soda hydrogen ti a bo ti o ni nickel.Alurinmorin ipo ni kikun le ṣee ṣe nipasẹ asopọ yiyipada dc.Ni -80 ° C weld irin si tun ni o ni ti o dara ikolu toughness.

NLO:

Welded -80 ° C ṣiṣẹ 1.5Ni irin be.

IṢẸ́ KẸ́MÍKÌ TÍ IRIN TI Ń ṢE:

| C | Mn | Si | Ni | S | P | |

| Standard | ≤0.08 | ≤1.25 | ≤0.60 | ≥1.00 | ≤0.035 | ≤0.035 |

| Idanwo | 0.045 | 0.60 | 0.27 | 1.80 | 0.010 | 0.015 |

IṢẸ́ IṢẸ́ TẸ̀RÁNÌ DÍRÍLẸ̀:

| Agbara Fifẹ Rm (MPa) | Ikore Agbara Rel (MPa) | Ilọsiwaju A (%) | -80°C Iye Ipa Ipa Akv (J) | |

| Standard | ≥490 | ≥390 | ≥22 | ≥27 |

| Idanwo | 530 | 445 | 30 | 100 |

IGBAKỌ NIPA (DC+):

| Iwọn (mm) | 3.2 | 4.0 | 5.0 | |

| Gigun (mm) | 350 | 400 | 400 | |

| Lọwọlọwọ (A) | 90-120 | 140-180 | 180-210 |

| E12015-G | Ni ibamu pẹlu GB E8515-G Ni ibamu pẹlu AWS E12015-G |

Ifarahan: E12015-G jẹ iru ẹrọ elekiturodu irin-kekere alloy giga ti o ni erupẹ kekere-hydrogen natrium iru.DCRP (Polarity Yipada lọwọlọwọ lọwọlọwọ).Gbogbo-ipo alurinmorin.

Awọn ohun elo: Ti a lo fun alurinmorin kekere alloy ti o ga, irin awọn ẹya pẹlu agbara fifẹ ti nipa 830MPa.

Iṣapọ Kemikali ti Irin Idogo (%)

| Kemikali Tiwqn | C | Mn | Si | S | P | Mo |

| Iye idaniloju | ≤0.15 | ≥1.00 | 0.4 ~ 0.8 | ≤0.035 | ≤0.035 | 0.60 ~ 1.20 |

| Abajade gbogbogbo | ≤0.10 | 1.50 | ≤0.70 | ≤0.020 | ≤0.020 | ~0.90 |

Mechanical Properties ti ohun idogo Irin

| Nkan Idanwo | Rm(MPa) | ReL tabiRp0.2(Mpa) | A(%) | KV2(J) |

| Iye idaniloju | ≥830 | ≥740 | ≥12 | - (iwọn otutu deede) |

| Abajade gbogbogbo | 860-950 | ≥750 | 12-20 | ≥27 |

Akoonu Hydrogen Diffusible ni Irin Idogo: ≤5.0ml/100g(Chromatography)

Ayewo X-ray Radiographic: ⅠIwe

Ilana:

1.The amọna gbọdọ wa ni ndin labẹ 350-400 ℃ fun wakati kan ki o to alurinmorin, fi sinu ohun idabobo le ati ki o waye ni kete bi won ti wa ni ti nilo.

2.Awọn abawọn lori weld bi ipata gbọdọ wa ni nso kuro, ati awọn weld gbọdọ wa ni preheated si nipa 200 ℃.

3.Weld le ti wa ni tempered labẹ 600-650 ℃ lẹhin alurinmorin ki bi lati se imukuro ti abẹnu wahala.